沸騰制粒干燥機(jī)

一、工作原理及應(yīng)用范圍介紹Introduction of Working Principle and Scope of Application

沸騰制粒方法是噴霧技術(shù)和流化技術(shù)的綜合運(yùn)用。 粉狀物料投入料斗內(nèi)密閉,在負(fù)壓熱氣流的作用,床體內(nèi)的粉末物料懸浮呈流化狀循環(huán)流動,流化的同時也呈均勻混料狀態(tài),同時噴入霧狀粘結(jié)劑潤濕容器內(nèi)的粉末,使粉末凝成疏松的小顆粒,成粒的同時,熱氣流對其作高效干燥,水份不斷蒸發(fā),粉末不斷凝固,最終形成理想的、均勻的多微孔球狀小顆粒物料粉末粒子。

沸騰流化制粒干燥機(jī)是將混合、制粒、干燥過程在同一設(shè)備內(nèi)一次完成, 故又稱“一步制粒機(jī)”。該機(jī)組為分批次間歇干燥生產(chǎn)方式。

本機(jī)廣泛運(yùn)用于制藥、食品工業(yè)中片劑、沖劑、顆粒果汁、調(diào)味品等造粒、包衣,也可用于農(nóng)藥、化工行業(yè)農(nóng)藥、飼料、化肥、染料等。

The boiling pelletizing method incorporates spray technology and fluidization technology. Powdery material is put into the hopper and enclosed. Under the action of negative pressure hot air, the powdery material inside the bed suspends and circularly flows in the fluidizing state. It is uniformly mixing when fluidizing, and at the same time mist-like binder is injected in to moisten the powder in the container so that the powder congeals into small loose granules. During the pelletizing, the hot air dries the material efficiently; water evaporates unceasingly; the powder congeals consistently, so ideal and uniform porous spherical powder granules are produced finally. The boiling fluidized pelletizing drier is to complete the mixing, pelletizing and drying processes at a time inside a same equipment, therefore it is also known as “one-step pelletizing drier”. This unit adopts batch drying production.

This equipment is widely applied to pelletizing and coating the tablets, dissolved medicines, juice granules and condiment etc in the pharmaceuticals and food industries, and also applicable to pesticides, chemical engineering pesticides, fodder, chemical fertilizer and dyes etc.

二、特點(diǎn)Characteristics

1.通過粉體造粒,改善流動性、減少粉塵飛揚(yáng),保持物料品質(zhì)均勻恒定。

2.通過粉體造粒改善其溶解性能。

3.混合、制粒、干燥過程在同一設(shè)備內(nèi)一次完成,提高綜合效率。

4.采用抗靜電濾布,設(shè)置壓力泄放孔,設(shè)備操作安全。

5.設(shè)備,裝卸料輕便快速、沖洗方便,符合“GMP”規(guī)范。

6.根據(jù)需要可實現(xiàn)全智能化、數(shù)字化、CIP等。

7.粘結(jié)劑霧化器采用多流體噴槍,霧粒均勻,成品合格率大大提高。

1. Pelletizing the powder improves the mobility, decreases flying dust and maintain the uniformity and constancy of material quality.

2. Pelletizing the powder improves the dissolving property of powder.

3. The mixing, pelletizing and drying processes are completed in a same equipment, which improves the overall efficiency.

4. Antistatic filter cloth is adopted and pressure relief hole is provided. The equipment operates safely.

5. The equipment is free of dead angles, easy and quick to load and unload the material and easy to be cleaned. It complies with “GMP” specifications.

6. It is possible to achieve full intelligence, digitization and CIP etc as required.

7. The binder atomizer adopts multi-fluid spray gun which produces uniform fog droplets. The pass rate of finished products is improved greatly.

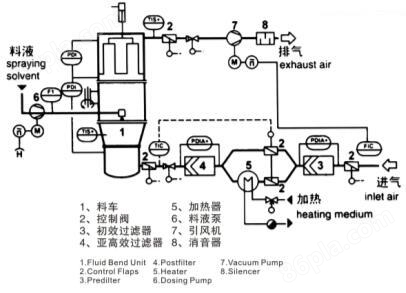

三、工藝流程圖Process flow diagram

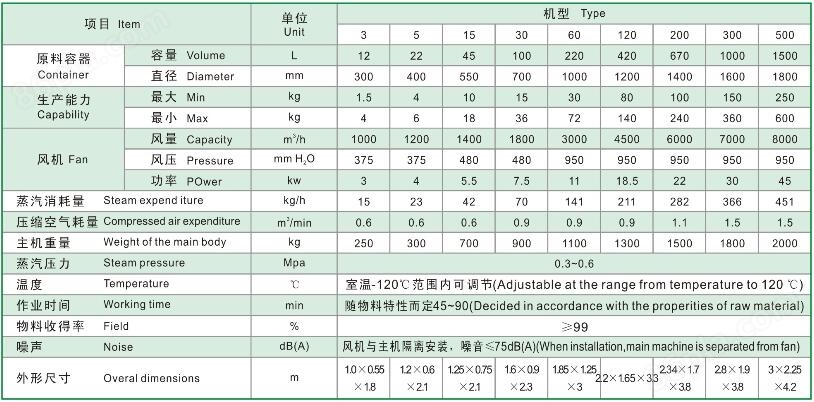

四、技術(shù)參數(shù)(下表中數(shù)值僅供選型時參考)

Technical parameters (the values in the table below are for reference in type selection only)

沸騰(流化)制粒干燥機(jī)Boiling (Fluidized) Pelletizing Drier

| 參考價 | 面議 |

具體成交價以合同協(xié)議為準(zhǔn)

- 公司名稱四川川大干燥科技工程有限責(zé)任公司

- 品 牌

- 型 號

- 所 在 地成都市

- 廠商性質(zhì)其他

- 更新時間2023/7/27 9:21:04

- 訪問次數(shù)366

四川川大干燥科技工程有限責(zé)任公司(簡稱:川大干燥)是于2001年成立的一家集技術(shù)研發(fā)、技術(shù)轉(zhuǎn)讓、裝備制造加工的企業(yè)。川大干燥行政管理與設(shè)計研發(fā)部門設(shè)在四川大學(xué)科技創(chuàng)新中心大樓內(nèi);生產(chǎn)和試驗科研基地位于成都羊安鎮(zhèn)工業(yè)園區(qū)內(nèi),并獨(dú)自建設(shè)有加工制造中心與產(chǎn)品測試展演中心。公司從建立之初即著力科技研發(fā),重心即著力醫(yī)藥、食品等方面的工藝技術(shù)研究與*裝備的研制上。公司具有門類學(xué)科齊全的專業(yè)研發(fā)隊伍,所研發(fā)的產(chǎn)品品質(zhì)優(yōu)良、性能可靠、外形美觀;經(jīng)過近三十年的產(chǎn)業(yè)技術(shù)研究、產(chǎn)品技術(shù)研制、產(chǎn)出技術(shù)研驗,已具有獨(dú)立自主知識產(chǎn)權(quán)的工藝及配方生產(chǎn)技術(shù)三項;固體制劑系列裝備已研制有十二類近兩百種不同規(guī)格。而今川大干燥嚴(yán)格按照新版GMP精心研制的制藥與食品裝備無論是在技術(shù)性能上,還是在性價比上都處于同行前列。現(xiàn)“川大干燥”的產(chǎn)品與服務(wù)無論在中國還是在世界各國的制藥、食品、保健品、動物藥業(yè)等行業(yè)以及其它行業(yè)均享有盛譽(yù),已經(jīng)形成特色與影響力的品牌。川大干燥除了在制藥與食品等行業(yè)提供良好技術(shù)服務(wù)與優(yōu)良產(chǎn)品以外,川大干燥還擁有包括工業(yè)粉塵凈化回收技術(shù)與系統(tǒng)工程裝備研制技術(shù)、大氣凈化環(huán)保工程裝備與家用PM2.5凈化器等系列產(chǎn)品技術(shù)。川大干燥向提供的優(yōu)良裝備產(chǎn)品有:各種烘干設(shè)備、各種造粒設(shè)備、各種混料設(shè)備、各種粉碎設(shè)備、各種篩分設(shè)備、各種滅菌設(shè)備、各種濃縮提取設(shè)備、各種環(huán)保設(shè)備等等。川大干燥向提供*的具有自主知識產(chǎn)權(quán)的工藝及裝備總包的項目有:l 雞精調(diào)味料工藝技術(shù)、工藝配方生產(chǎn)技術(shù),雞精調(diào)味料全套生產(chǎn)線。l 高品位高純度三偏磷酸鈉工藝生產(chǎn)技術(shù)以及生產(chǎn)線(川大干燥起草的三偏磷酸鈉國家標(biāo)準(zhǔn)已于2015年3月正式公布實施)。l 鮮榨提取制取方便型老姜湯沖劑工藝技術(shù)以及全套生產(chǎn)線等等。

真空干燥設(shè)備

沸騰制粒干燥機(jī)一、工作原理及應(yīng)用范圍介紹IntroductionofWorkingPrincipleandScopeofApplication沸騰制粒方法是噴霧技術(shù)和流化技術(shù)的綜合運(yùn)用

沸騰(流化)制粒干燥機(jī)Boiling (Fluidized) Pelletizing Drier 產(chǎn)品信息

關(guān)鍵詞:干燥機(jī)

在找 沸騰(流化)制粒干燥機(jī)Boiling (Fluidized) Pelletizing Drier 產(chǎn)品的人還在看