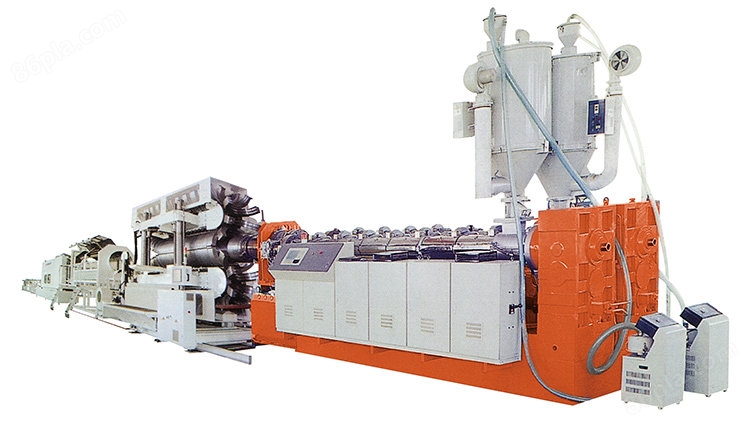

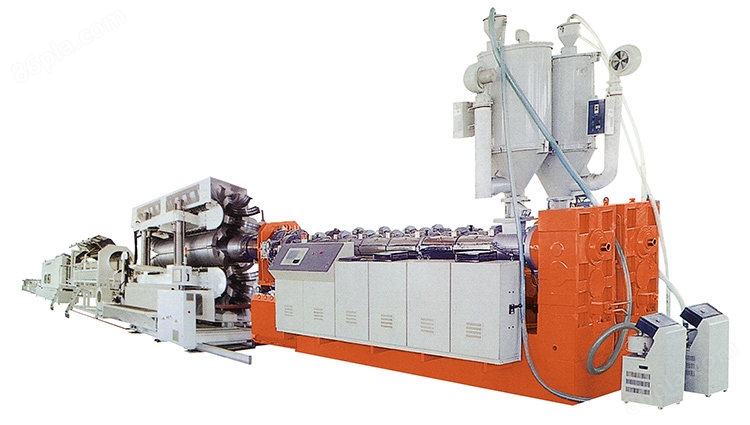

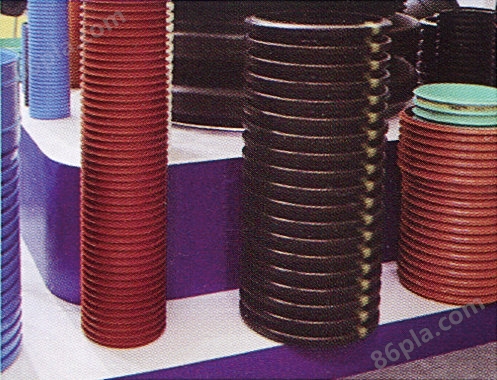

雙壁波紋管生產(chǎn)線

Double wall corrugated pipe extrusion line

用途及特點(diǎn)/Application

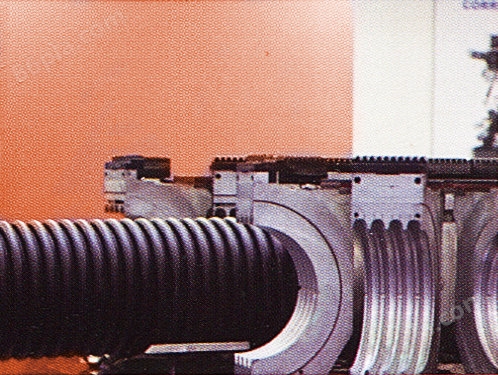

經(jīng)專業(yè)設(shè)計(jì),精心制造的(Φ200-Φ600)HDPE/PVC雙壁波紋管擠出生產(chǎn)線,具有產(chǎn)量高、擠出穩(wěn)定和自動(dòng)化程度高等優(yōu)點(diǎn)。擠出機(jī):擠出機(jī)可根據(jù)用戶原料情況特殊設(shè)計(jì),HDPE采用新型高效單螺桿擠出機(jī),PVC采用大型平雙或錐雙擠出機(jī)。模具及輔機(jī):成型機(jī)及機(jī)頭精度高,模塊互換性好,模塊冷卻方式有水冷和風(fēng)冷兩種,確保成型管材的各項(xiàng)性能指標(biāo),整條生產(chǎn)線具有很高的自控功能。

It is fully computer controlled. automatic production line(Φ200-Φ600).It has features of high and stable output capacity, and highly automatic operation. According to the material situation, for HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin screw extruder or parallel twin screw extruder: The forming system of this line consists of mould and corrugator. The mould blocks can be easily changed and they are equiped with air or water cooling system. The production line can also be equipment with siemens company logic control system.

主要技術(shù)參數(shù)/Main technical parameters

型號(hào)Model | BW-IV型BW-IV series | BW-A型BW-A series |

功率Power | 11kw | 15kw |

模具規(guī)格Mould specification | Φ200mm-Φ400mm | Φ300mm-Φ600mm |

模具材質(zhì)Mould material | 特殊鋁合金Special aluminum alloy | 特殊鋁合金Special aluminum alloy |

模具周長(zhǎng)Mould perimeter | 7m | 7m |

模具冷卻形式Mould cooling way | 風(fēng)冷Air cooling | 風(fēng)冷Air cooling |

生產(chǎn)速度Production speed | 0.5m-2m/min | 0.5m-2m/min |

生產(chǎn)原料Production material | PVC/HDPE | PVC/HDPE |

主機(jī)選擇Main machine | 單/雙螺桿擠出機(jī)Twin-screw extruder / Sinple screw extruder | 錐形單/雙螺桿擠出機(jī)Twin-screw extruder / Sinple screw extruder |