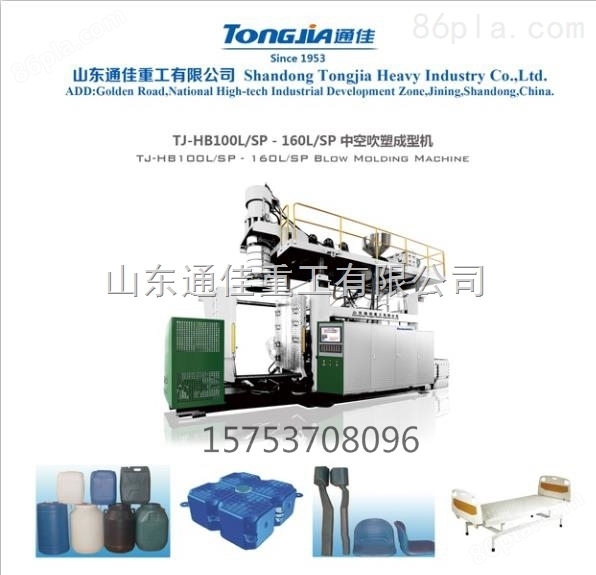

吹塑機(jī)價(jià)格/報(bào)價(jià)信息

通佳重工塑料機(jī)械公司供應(yīng)20-500L塑料桶生產(chǎn)設(shè)備,該系列設(shè)備采用兩線配置,專業(yè)用語生產(chǎn)各種化工用塑料桶、如同、,醫(yī)藥包裝,兒童安全座椅,交通設(shè)施和工具箱包等,滿足用戶對(duì)20-500L不同規(guī)格中空制品的需求。

山東省濟(jì)寧市高新區(qū)黃金大道

吹塑機(jī)價(jià)格/報(bào)價(jià)信息

設(shè)備基本配置及參數(shù) TJ-HB15L

Technical Data for Blow Molding TJ-HB15L

- 基本參數(shù)General Issues

1.1設(shè)備操作說明包括液壓、氣動(dòng)、操作系統(tǒng)、冷卻系統(tǒng)等

Machine operating manual including Hydraulic, Pneumatic, Assembly drawing, Cooling water.

1.2zui大制品容積:15L

Max. volume of product: 15L

1.3設(shè)備重量:7 ton

Total weight 7ton

- 開合模Clamping Unit

2.1合模裝置為雙拉桿結(jié)構(gòu),容模空間大且更換模具方便

Principle: bi-direction synchronous clamping device with double axis.

2.2直線導(dǎo)軌運(yùn)動(dòng)

Linear roller guidance horizontal

2.3鎖模力:90KN

Clamping force: 90KN

2.4模板尺寸 H x W :380x 425 mm

Mold platens H x W : 380x 425 mm

2.5模板開距:230-620 mm

Distance between the platens: 230-620 mm

- 模頭Die Head

3.1連續(xù)擠出式結(jié)構(gòu)模頭

Type of die head: Continuous.

3.2*先出

FIFO

3.3口模直徑:Φ25-80mm

Die diameterΦ25-80 mm

3.4 300 點(diǎn)軸向壁厚控制

300 point WDS system controller

3.5熱電偶類型:K

Type of temperature sensors: K

3.6模頭加熱功率:5.6 KW

Power of heating: 5.6 KW

- 擠出系統(tǒng) Extruder System

4.1適合加工原料:HDPE, PP

Extruder should be adequate to work with HDPE, PP

4.2螺桿直徑:75mm

Screw diameter: 75mm

4.3螺桿長(zhǎng)徑比:25:1

Screw length diameter ratio: 25:1

4.4機(jī)筒、螺桿氮化處理

Nitride treatment barrel and screw.

4.5塑化量:80KG/H

Plasticizing efficiency: 80 kg/h (HDPE)

4.6進(jìn)料段有冷卻水套強(qiáng)制冷卻

Feeding zone grooved with cooling water.

4.7熱電偶類型:K

Type of temperature sensors: K

4.8擠出電機(jī)功率:22KW (AC)

AC motor drive: 22 KW

4.9鑄鋁加熱器,加不銹鋼外包

Cast-aluminum heater with heater preserving and protection cover of stainless steel.

4.10加熱功率:11 KW

Heating power: 11 KW

4.11 4組風(fēng)機(jī)冷卻

Cooling by4 cooling fans.

4.12料斗有檢測(cè)原料水平面視窗,料斗連接處有氣動(dòng)止位閥

Raw material hopper with a window.